Highly responsibility makes well performance

E-mail: sales@highlywell-china.com

Highly responsibility makes well performance

E-mail: sales@highlywell-china.com

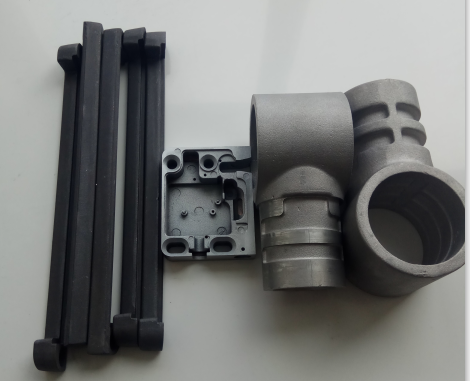

Difference of die casting parts and gravity die cast parts, can be distinguished as follows:

Gravity die casting - GDC, also called permanent mould casting, is a repeatable casting process used for non-ferrous

alloy parts, in particular, aluminium, zinc and copper base alloys.

The process differs from high pressure die casting in that, gravity, rather than high pressure is used to fill the mould

with the liquid alloy. Gravity die casting is suitable for medium to high volume products,and normally the parts are of

heavier sections than high pressure die casting, but thinner sections than sand casting.

High pressure die castings are of better surface finish, and high production efficiency, as well as less machining,

and thus better unit price, and the surface can be polished, power coated, chrome plated, and anodized too.

The only disadvantage is that, the metal mould cost normally is high, comparing with the gravity die casting.

It is a wise way to consider which process should be chosen, according to the order quantity, surface quality,

part structure, wall thickness, etc.